Gas Meter Pulse Output

Why?

As can be seen from the Analytics page here, understanding energy consumption can lead to significant savings. Building on the electricity "Smart meter" experience the intention here is to include real-time gas consumption information into the Analytics cluster for similar analysis.

However, distributor administrative absurdity appears to mean a cost of some $850 (on top of some $400 to change the meter) to read data compared to an extremely simple solution which would cost about $10 (BTW the initial esimates were around $2,500).

Update: 2023.07.19

@kazipi points out that "I'm spending $10+ per day on gas so need to monitor and work out some changes". Some quick research shows that the "Gas Cartel" has engineered severe price rises in the wake of the Ukraine war.

Gas Giants Reap $40 Billion in Windfall War Profits: Report

"New analysis shows Liquified Natural Gas (LNG) producers reaped up to $40 billion of windfall profits in FY 2021-22 thanks to soaring global gas prices due to the war in Ukraine.

The research comes following a damning report from the ACCC into the gas industry around price-fixing and subsequent condemnation of cartel-like behaviour on the east coast gas market."

---

The Gas Meter

Historically the lineage of the gas meter can be traced back to England in the year 1844 invented by Thomas Glover. Today's gas meters, like the one outside the front of your house, pretty much hasn't changed since 1946. As you can imagine, the bureaucracy and regulations that have evolved over the centuries are hardly scientifically based as any insurance actuary will tell you.

In fact gas meters are more or less dangerous, from a regulatory point of view, depending on which Australian state you live in. Add to this the complete absence of any "smarts" or even any attempt at adding smarts to this antequated piece of technology and you can see how the gas distrubution network has fallen in to decay. As an example, the venerable old gas meter can't even compensate properly for gas temperature variations leading to the absurd situation where billing for energy content is a variable thing.

It would seem that allowing users to actually measure such energy variations is the last thing the stagnant old distribution networks wants.

A brief history of the gas meter ( Dr. Phys. Monica Sabina Crainic - PDF)

While I'm still searching for a viable solution here, it has occured to me to leave the gas network completely.

The gas retailer

Talking to the gas retailer is pretty much a complete waste of time. They more or less don't even know what gas is, which is similar to the electricity retailer (for example you can try asking your electricity retailer what electricity is - lol).

Distributors

Communicating with the network people is a different kettle of fish. They know lots and lots, and in the case of electricity, are even helpful and are able to do things in very good time. Gas is a slightly different story.

From my experience, it seems the Victorian gas distributors are not equipped to provide real time information to home owners (otherwise known as effected parties) as required by the regulatory documentation, although they know what is it and what it means. (Link - Victorian Gas Distribution Code).

My gas distributor claimed I am the only home owner they have ever encountered that has requested a "pulse output", a claim I checked with the network's contract gas engineers. The engineer also claimed that in his experience he had never encountered such a request either. This seems at odds with the Victorian government's $2 billion expenditure on electricity "Smart Meters" installed in all houses in this state.

Essentially it is suggested that I'm the only person in Victoria who wants energy information for gas consumption of a type similar to the universally available electricity data. This in itself raises questions regarding domestic gas consumptiion and if anyone has ever accurately correlated it against time of day usage in this state.

Distributor Proposed solution

Essentially the distributor has proposed to replace the gas meter with a type that has the necessary "kit" pre-installed for a fee, which after being marked up by the retailer, came to something like $450.

After considereable too-ing and fro-ing I suggested the manufacturers solution outlined below, complete with the part number and point of purchase. It is claimed the field installation process, in the kit's instructions, should take some 5 minutes.

This is indeed acceptable to the distributor, however, that option would cost some $550 odd, which is more than replacing the entire meter.

| As an aside, I pointed out that when this current meter was installed a couple of years ago, the gas team failed to turn on the gas valve afterwards. As we were on holidays in europe at the time we recieved frantic phone calls about a gas failure, leading to a gas plumber call out. Eventually the plumber turned the gas on again and problem was solved. Finally the costs for the callout were recovered from the distributor. |

Recent developments

Intrinsic Safety

It was then that the distributor pointed out that if I went ahead and independently installed the kit, that an audit would need to be conducted to verify "Intrinsic Safety" and such an audit would be conducted by their contract gas engineers. All associated costs would then be passed on.

In further correspondence it was pointed out, in good faith, that:

"if something happens (ie ignition of gas at the meter) and the problem originated from the Z-wave, or anything that supplied to the Z-wave, insurance will not cover the damage. Not to mention the legalities of not connecting as per the standard."

However, in attempting to corroborate this, I came across an open letter from the ESV which appears to contradict this. At this stage I'm attemtping to clarify the situation, as it would appear that my gas meter may not be a "hazardous area".

| "Energy Safe Victoria (ESV) is aware of consultants and electrical inspectors incorrectly classifiying some industrial and commercial gas installations and their gas appliances as hazardous areas. Such an error may cause unnecessary additional costs and delays and in some cases, increased gas safety risk." |

Download the full pdf from ESV

OK, so the clarification is:

|

Hi, Thank you for your email, the letter you refer to in your email below covers downstream (of gas meter) installations for commercial and industrial gas installations only. Gas meters of any type form part of the gas distribution network. The gas meter is an asset of your particular gas distribution company and therefore any adjustments to this asset would be carried out by the distribution company. Hope this answers your question Regards

|

From what I can understand, the gas meter has high pressure coming in from the street and low pressure going in to my house. So if the low pressure side springs a leak then not much gas will come out. However, if the high pressure side springs a leak, heaps of gas could come out.

The practical upshot is: the gas meter is designated a "hazardous area" and so various rules and regulations apply (and lots of them too).

Gas Monitoring a good basic tutorial. UK legislation

Hazardous Area Certification. A good explanation of various levels of hazardous areas

So it seems (and this needs technical verification from the appropriate body) that my gas meter would be classified as:

| Type of area | NEC and CEC* | ATEX and IEC | Definitions |

| Hazardous under abnormal conditions | Division 2 | Zone 2 / Zone22

Cat 3 |

A place in which an explosive atmosphere is not likely to occur in normal operation, but may occur for short periods |

The apparent absurdity

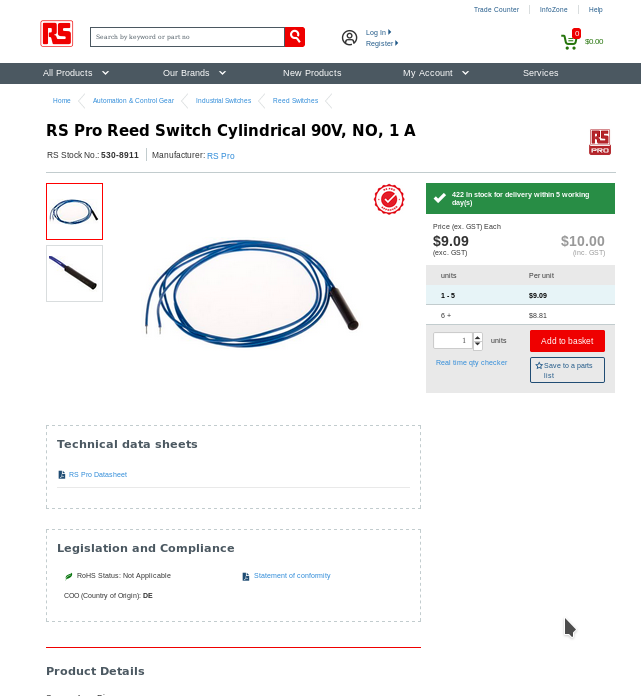

Upon mentioning my attempts at getting access to real-time gas meter data, one person mentioned this extremely simple solution. Just buy a reed switch and blue tack it in place near the little internal spinning magnet. Total cost $10.00 compared to some $800.

Notes on "shipper form" from distributor

|

Multinet can supply and install a pulse point for this property as requested by the applicant.

Multinets approved contractor is GTS, who maintains and carries out all Instrumentation work for Multinet Gas. Multinet would prefer that the customer use GTS to install any instrumentation equipment (Energy Management Systems) when connecting to Multinet Gas assets/meters.

If the customer independently connects to our meter, Multinet will ensure GTS audit the installation for compliance to Australian Standards, Multinet procedures and to ensure intrinsic safety within hazardous zones. Any cost incurred for GTS services will be passed directly onto the applicant.

Robert xxxxxxxx

David xxxxxxxx

Multinet will raise own service order upon acceptance. |

The regulatory framework

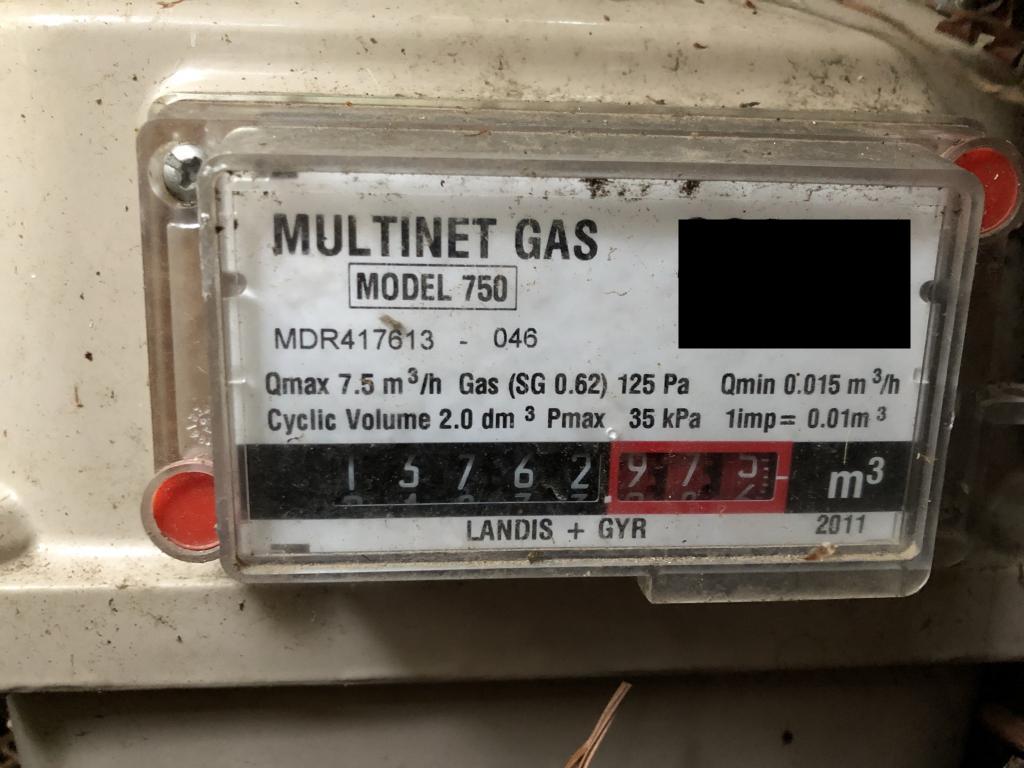

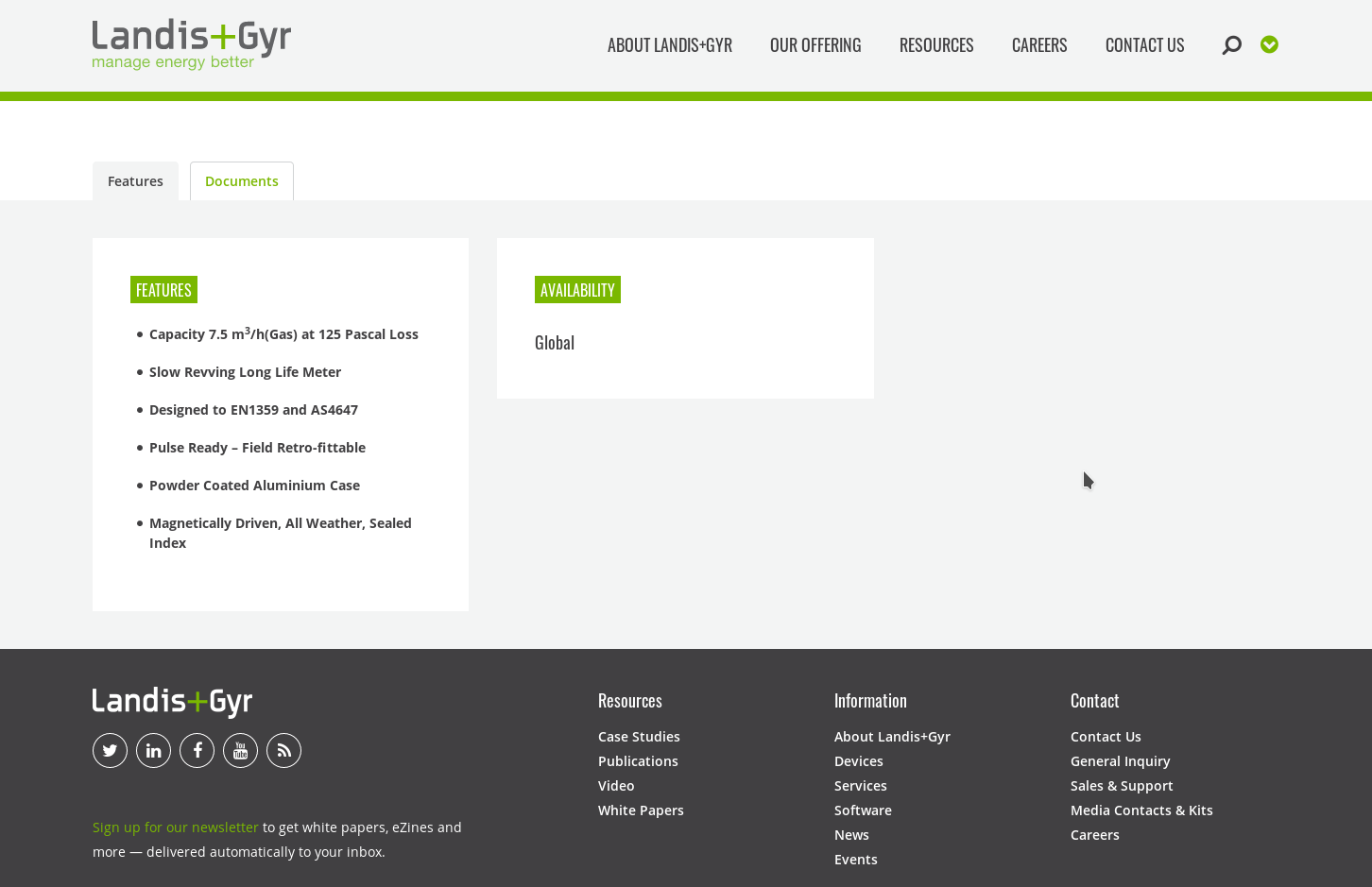

The meter installed at home here is the Landis + Gyr Model 750.

This meter has been designed and built to AS 4647-2011 (R2018).

download pdf (local copy retrieved 17 sep 2018)

Among its key features listed in the following screen capture from the manufacturers website: https://www.landisgyr.com/product/750-2/

is "Pulse Ready - Field Retro-fittable"

Inspection of the meter fitted here shows that there is indeed provision for a pulse output attachment (see the photos below - some can be viewed in higher resolution). In fact the name plate even states "1imp=0.01m3" (meaning 1 impulse for every 0.01 cubic meters of gas) demonstrating the extent to which pulse output is a designed in feature.

The "Pulse Output" refered to is described on the website as ( https://www.landisgyr.com/product/landisgyr-domestic-pulse-output/ ) :

Description:The pulse output device is a magnetically actuated, voltage-free reed switch where the electrical instrumentation attached provides the power to detect the opening and closing of the reed switch. Reed switch is rated to 24Vdc, 50mA, 0.25W Form A normally open. Two types of pulse modules are available: 750082 – two reed switches, one for meter pulse one normally closed for tamper detection and 750083, which has just one reed switch for meter pulse. The pulse rate output is 1 pulse per 10 litres or 0.01 m3. Suitable for use on the BK1.6, Model 750 and Model 1010 gas meters. All these meters are fitted with a magnet in the last index wheel and hence each meter is pulse retro-fittable while in service by use of either Pulse Module without the need to interfere with the metrology of the meter or the meter seals. The Standard Electronic Pulse Output Kit (part number 750085) includes pulse module (IN- Z61), cable and plug (32446432), and screw (15006), bush and nut (BK Nut) for connection to the meters index. Two lead seals are also supplied: one to seal the plug in place, the second can be used instead of the screw and nut. |

IN-Z61 to Z65 technical drawings and specifications

Installation, Comissioning and Maintenance Manual for Pulse Output Kit

Similar IN-Z61 installations

http://biomassproducer.com.au/wp-content/uploads/2013/09/Grantham-piggery-fact-sheet.pdf

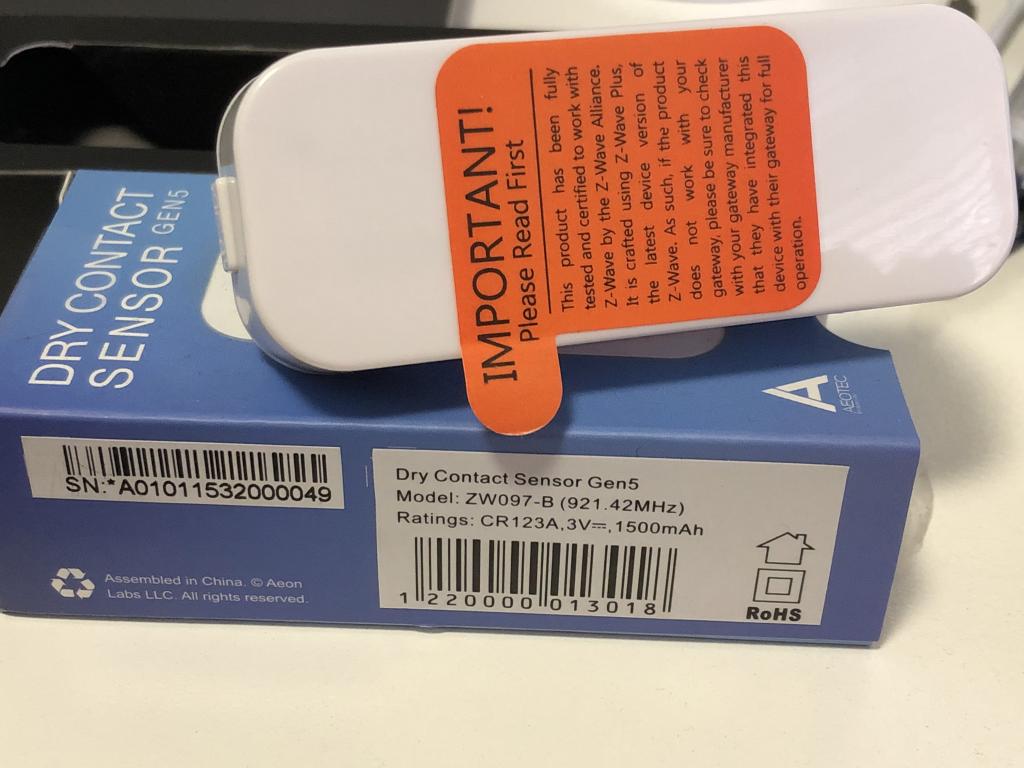

Z-Wave

Z-Wave dry contact sensor battery operated. As this device is not certified intrisically safe an additional certified isolator is required.

Gas Safety Legislation in Victoria

https://www.esv.vic.gov.au/about-esv/legislation-and-regulations/legislation-administered-by-esv/

List of standards:

| AS 4647-2011 (R2018) | Diaphram Gas Meters |

| AS/NZS 60079.29.2:2008 | Explosive atmospheres Gas detectors - Selection, installation, use and maintenance of detectors for flammable gases and oxygen |

| AS 2331.3.12-2006 (R2017) | Methods of test for metallic and related coatings Corrosion and related property tests - Cyclic salt fog/UV exposure of organically coated metal |

| AS/NZS 60079.25:2004 | Electrical apparatus for explosive gas atmospheres Intrinsically safe systems |

| AS/NZS 60079.28:2007 | Explosive atmospheres Protection of equipment and transmission systems using optical radiation |

| AS/NZS 60079.17:2009 | Explosive atmospheres Electrical installations inspection and maintenance (IEC 60079-17, Ed.4.0(2007) MOD) |

| AS/NZS 60079.2:2007 | Explosive atmospheres Equipment protection by pressurized enclosure ‘p’ |

| AS/NZS 60079.30.2:2007 | Explosive atmospheres Electrical resistance trace heating - Application guide for design, installation and maintenance (IEC 60079-30-2, Ed. 1.0 (2007) MOD) |

| AS/NZS 60079.14:2009 | Explosive atmospheres Electrical installations design, selection and erection (IEC 60079-14, Ed. 4.0(2007) MOD) |

| AS/NZS 60079.18:2005 | Electrical apparatus for explosive gas atmospheres Construction, test and marking of type of protection encapsulation ‘m’ electrical apparatus |

| AS/NZS 1580.481.1.9:1998 (R2013) | Paints and related materials - Methods of test Coatings - Exposed to weathering - Degree of blistering |

| AS/NZS 60079.6:2007 | Explosive atmospheres Equipment protection by oil immersion 'o' |

| AS 2331.3.10-2001 (R2017) | Methods of test for metallic and related coatings Corrosion and related property tests - Cracks and pores in chromium |

| AS/NZS 60079.15:2006 | Electrical apparatus for explosive gas atmospheres Construction, test and marking of type of protection, ‘n’ electrical apparatus |

| AS/NZS 60079.20:2000 | Electrical apparatus for explosive gas atmospheres Data for flammable gases and vapours, relating to the use of electrical apparatus |

| AS/NZS 60079.12:2000 | Electrical apparatus for explosive gas atmospheres Classification of mixtures of gases or vapours with air according to their maximum experimental safe gaps and minimum igniting currents |

| AS 1580.408.4-2004 | Paints and related materials - Methods of test Adhesion (crosscut) |

| AS/NZS 60079.10.1:2009 | Explosive atmospheres Classification of areas - Explosive gas atmospheres (IEC 60079-10-1, Ed.1.0 (2008) MOD) (Ruling 1 to AS/NZS 60079.10.1) |

| AS 1580.481.3-2002 (R2013) | Paints and related materials - Methods of test Coatings - Exposed to weathering - Degree of corrosion of coated metal substrates |

| AS 2331.3.11-2004 (R2017) | Methods of test for metallic and related coatings Corrosion and related property tests - Chemical residue tests |

| AS 2331.3.1-2001 (R2017) | Methods of test for metallic and related coatings Corrosion and related property tests - Neutral salt spray (NSS) test |

| AS 1834.2-1986 (R2018) | Material for soldering Flux-cored solders |

| AS 4564-2005 | Specification for general purpose natural gas |

| AS/NZS 60079.1:2007 | Explosive atmospheres Equipment protection by flameproof enclosures ‘d’ |

| AS 1199.1-2003 (R2016) | Sampling procedures for inspection by attributes Sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection |

| AS 4670-2006 | Commercial propane and commercial butane for heating purposes |

| AS 2706-2003 (R2018) | Numerical values - Rounding and interpretation of limiting values |

| AS/NZS 60079.7:2006 | Explosive atmospheres Equipment protection by increased safety 'e' |

| AS/NZS 60079.30.1:2007 | Explosive atmospheres Electrical resistance trace heating - General and testing requirements |

| AS/NZS 60079.5:2007 | Explosive atmospheres Equipment protection by powdered filling 'q' |

| AS/NZS 60079.27:2008 | Explosive atmospheres Fieldbus intrinsically safe concept (FISCO) |

| AS/NZS 60079.1.1:2002 | Electrical apparatus for explosive gas atmospheres Flameproof enclosures 'd' - Method of test for ascertainment of maximum experimental safe gap |

| AS 2331.3.13-2006 (R2017) | Methods of test for metallic and related coatings Corrosion and related property tests - Wet (salt fog)/dry/humidity |

| AS/NZS 1580.405.1:1996 (R2013) | Paints and related materials - Methods of test - Determination of pencil hardness of paint film |

| AS/NZS 4944:2006 (R2017) | Gas meters - In-service compliance testing |

| AS/NZS 60079.29.1:2008 | Explosive atmospheres Gas detectors - Performance requirements of detectors for flammable gases |

| AS/NZS 60079.0:2008 | Explosive atmospheres Equipment - General requirements |

| AS/NZS 60079.26:2007 | Explosive atmospheres Equipment with equipment protection level (EPL) Ga |

| AS 1834.1-1991 (R2018) | Material for soldering Solder alloys |

| AS/NZS 60079.4:2000 | Electrical apparatus for explosive gas atmospheres Method of test for ignition temperature |

| AS/NZS 60079.11:2006 |

Explosive atmospheres Equipment protection by intrinsic safety ‘i’ |

Open letter from ESV which does not apply to gas meters.